Case Studies

X-Tek: Carving out a Niche Market in Specialised Inspection

Founded in the early 1980s, X-Tek was originally conceived as a custom design facility for microfocus x-ray systems. The company rapidly expanded into volume production of high-quality, high-precision, standard and custom-designed x-ray inspection systems for the aerospace, automotive, medical and general manufacturing industries. Over the past 6 years X-Tek has undergone rapid growth, moving to a much larger manufacturing site and increasing the workforce. In 1997, the company established X-Tek LLC, a sales and service office in Santa Clara, California, at the heart of Silicon Valley. X-Tek also maintains a world-wide network of sales agents. The company has an international user base, with installations throughout Asia, the USA and Western Europe. Major multinational companies using X-Tek equipment include AMD, GEC, General Motors, Matra, Motorola, Samsung and Rolls Royce.

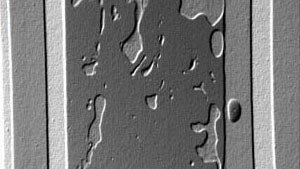

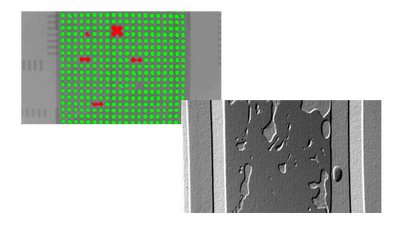

A few years ago X-Tek began concentrating its efforts on the burgeoning electronics industry - in particular the packaging of ICs and components. The problem of 'voids' or bubbles within a chip's package was well known and a constant frustration to chip manufacturers, as was the quest for a satisfactory means of examining the quality of the wire bonding within the packaging. In the manufacturing process, silicon chips are placed onto a substrate using epoxy glue. Voids can form within the glue during placement and these can give rise to gaseous expansion when the chips heat up on being powered and the expansion can distort and crack them. Just as seriously, the voids partially insulate the chips, leading to delamination, where the chip actually detaches from the substrate. Manufacturers therefore need to know the quantity of voids within the chip package and x-ray has proven to be the only viable means of inspecting a product that cannot be examined without destroying it. Inspection may involve every chip, in military applications for instance, or more commonly batches, for commercial products.

Andy Foster, X-Tek's Senior Engineer, commented that, contrary to popular belief, silicon chips are not susceptible to damage from x-rays as long as they are not powered up when examined. X-ray bombardment of powered chips can cause damaging free electrons to be thrown off into the silicon. Silicon chips can in fact withstand very high doses of x-rays without harm, but as Foster pointed out, X-Tek systems only deliver minute doses anyway.

X-Tek systems are controlled by industrial rackmount PCs, with standard PCI motherboards, running exclusively on Windows NT. The modular nature of X-Tek's own iXS control software means that the Matrox Imaging Library (MIL), a comprehensive development toolbox for image capture and processing applications, is ideally suited to the X-Tek approach. Image processing is therefore kept separate from the manipulator and x-ray control modules. Foster commented: &quuot; went for a development library rather than an off-the-shelf program, because we needed to bring all the different functionalities together into one package, but still be able to develop them separately ourselves."

Although X-Tek systems currently uses Matrox Pulsar frame grabber boards for image capture, the company is planning a two-tier approach, utilising Matrox Meteor-IIs for lower-end applications. This will make budget systems as cost-effective as possible, while Matrox Corona boards will be used for more costly, higher-end applications. Uniquely, in these days of outsourcing and JIT manufacturing, the image intensifier, camera and high-voltage generator are the only other bought in components in an X-Tek system. The x-ray gun is a specialised micro-focus unit that gives much higher resolution than those found in the crowded security x-ray market.

X-ray emissions are random by nature, which means they create 'speckled' images for capture by the frame grabbing board in the PC, so the first processing task is to clean up each image, which is done by acquiring several frames and averaging their contents. Front-end software has been written by X-Tek to create an image capture and processing application, utilising the Matrox Imaging Library so that brightness, contrast and gamma can be adjusted, while pseudo-3D filters can also be applied to give artificial depth to the view. These filters are based on standard Matrox filters for edge enhancement and sharpening, amongst others. Each captured view can then be labelled for easy identification prior to saving.

The digital components of PimaxScan include a Uniqvision UP930 Camera Link camera, a Matrox Helios XCL frame grabber, and an embedded PC fitted with an Intel 915-based motherboard and an Intel Pentium 4 processor. The system runs Windows XP Embedded. All the software was designed in C++ and built with the Matrox Imaging Library (MIL). Not only does the software control image acquisition, display and archiving, but the image processing as well. "MIL provides all the algorithms and functions for processing. In particular we used the Edge Finder module for border detection, as well as Low-pass filters, recursive filters, rotations, and digital subtraction," explains Sentoni. "We also used some LUTs to enhance the images for display on dual-screen terminals."

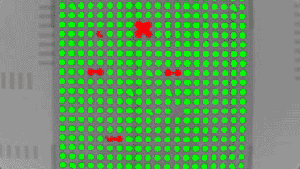

More advanced X-Tek systems utilise an RS232-based x-ray controller and have fully-programmable servo-manipulators with teach and learn capabilities. Ever-watchful of market trends in its aggressively competitive target markets, the company is looking at adding auto-loading and unloading capability, so that its systems can be integrated into production lines. The primary area of automation currently being evaluated is ball-grid array inspection, as there is currently no satisfactory automated way of examining soldered joints. After PCBs pass through various reflow and soldering stages they would arrive at the x-ray system for joint-quality inspection. Foster says that X-Tek has developed automated software utilising the blob analysis features of MIL to look for solder balls that are linked, missing or malformed.

Foster went on to explain how X-Tek selected a supplier of image capture/processing software and hardware: "We knew we wanted a frame grabber and an imaging library. Boards from all the leading manufacturers were evaluated, but it proved difficult to make the third party libraries talk to the frame grabbers, with software and hardware companies tending to blame each other for the lack of communication." Somewhat tongue in cheek he added: "With the library and hardware coming from one company, we knew who we could blame if there were problems and it turned out only Matrox was able to offer both products. Basically, integration of the Matrox Pulsar board and MIL has worked very well in terms of getting the image up on the screen and starting to work with it." In 1999, X-Tek is also planning to migrate application development to VBA (Visual Basic for Applications) so its customers can modify code for themselves and integrate their applications with office software suites for automatic report generation.

New X-Tek software makes extensive use of Matrox's ActiveMIL-Lite. Future development may have to port to OS/2, on which many production lines are based, but Foster is sanguine about the prospect. Design-in time for X-Tek systems is very short and customers can expect delivery within 10-12 weeks, which includes tailoring hardware and software to specific needs. Customisation may include writing or modifying modules to examine particular features of a chip, for example where there are 'via' holes beneath it, which usually involves fine-tuning existing software algorithms.

"ActiveMIL-Lite has turned out to be a real boon", Foster commented, "I really see it as a very significant step forward. It's robust, and in a Visual Basic environment is easier to handle than MIL. We're really looking forward to the full version of Active MIL coming out, but happily the 'light' version is currently giving us the image processing features we need, in conjunction with the imaging DLL.

The downturn in the far eastern electronics industry has had little impact on X-Tek's traditional business because, as Foster remarked, penetration to date for the company's systems has claimed less than one percent of the overall potential market. Foster therefore sees a huge potential market for x-ray in semiconductor manufacture. In the past, manufacturers have made high volumes of large-scale integrated circuit chips, simply discarding any that didn't work. Eliminating chips with physical faults before functional testing reduces costs, because testing is expensive. Foster believes that the highly competitive nature of the semiconductor industry can only benefit X-Tek, because with margins under so much pressure, maximising yield is vital. Manufacturers are proving quick to pick up on the benefits of costing-in x-ray inspection facilities, both for new Fabs and for existing plant. So with only two other major players in the world, the future looks very bright for X-Tek.

For more information contact Media Relations.