Case Studies

Vision Rules!

Intelligent vision system ensures every product gets camera time

Rules are made to be broken, the old saying goes. Maybe it's human nature. Once a rule is imposed by authority, the temptation is there to break it, whether it's a speed limit or a curfew. Or a shampoo bottle.

A global brand of personal care products found some of its own plant staff were breaking the rules, letting products with incorrect or misaligned labels slide through the vision system. Sometimes, an operator might be at the end of a shift, or have a quota to fill and be at risk of running out of time. Whatever the reasons, the manufacturer discovered that some plants employed clever, and often low-tech strategies for bypassing the vision inspection process. Sometimes the plant staff would simply shut off the vision sub-system and let the products go through without inspection. Other times the staff would place an image of a good product in front of the camera; naturally, the products "inspected" this way had a 100% pass rate!

When this company explained the issue to CI Vision (Aurora, IL), one of their requirements was a mechanism to prevent plant staff from bypassing the vision system. "They needed something fool-proof," explains Tom McLean, COO at CI Vision. McLean calls CI Vision's fool-proof strategy "Anti-Vision Circumvention Technology". It's one of the interesting new features of the company's Pro Series, a line of inspection systems for contract packagers.

The system

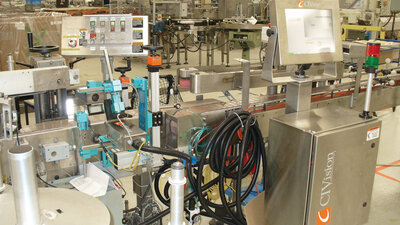

When a product batch is ready for inspection, an operator sets up the inspection type on a touch-screen interface; the same interface used on all CI Vision products. The base model features two GigE Vision® cameras in steel housings that are installed on either side of the conveyor where the products pass; up to four cameras can be installed depending on the customer's requirements. The vision system is controlled by a custom-built PC, but some units are shipped with the Matrox 4Sight X industrial PC. The CIVCore® software that controls the image acquisition and inspection tasks is built from the Matrox Imaging Library (MIL).

When an image is acquired, normalized grayscale correlation is used to determine the presence or absence of the label itself, as well as the location of the label's region of interest that contains a bar or matrix code, or a lot number. Code 128 one dimensional and Data Matrix two dimensional codes are read by MIL's code module for readability and checked for correctness. The CIVCore®'s OCV module can read texts of lot numbers, product codes, and Label Control Numbers (the manufacturer's code for the product and its label), and is built from MIL's pattern matching and image processing modules.

The Pro Series features an optional tool that detects if the same label appears on the front and back of the product. The system uses the search model from the presence / absence feature to determine which label is in front of the Camera 1. With that result, the system automatically instructs the second camera to look for the other label. If the second camera fails to find it, the system concludes that the product has the same label on both sides.

Passing with flying colors (or not): Anti-Vision Circumvention Technology

If the product fails any inspection, it gets flagged and diverted off the line. But as CI Vision's customer discovered, sometimes plant staff let non-conforming labels go through. Rick Koval, Lead Software Engineer at CI Vision, implemented a three-part strategy to ensure the system inspects 100% of the products.

Koval's strategy was to make sure that the vision system operated with other automation equipment at all times. In other words, when the labeler is running, the vision system must also be running as well. During operation, the vision system uses image acquisition trigger inputs as a mechanism for determining the product's presence so it can be inspected. If a certain number of seconds pass without a trigger while the labeler's 'run' signal is detected, the vision system faults and outputs a signal to shut down the line. Similarly, when the labeler is off (i.e., there is no 'run' signal) and the vision system receives triggers, the labeler outputs a signal to shut the line down. A fault signal also switches on a red tower light.

The most important strategy to thwart the attempts to bypass the vision system is the intelligence that detects if the camera is acquiring fake images. In this case the software checks for movement between the acquired images by comparing translation results. MIL's pattern matching algorithms give the location results of the label's features. Then the locations are compared from image to image over the sequence of acquired images. If a certain number of images indicate no movement between them, the current part and all future parts will fail. The user controls the number of images to compare and the tolerance for movement, and the parts will continue to fail until the movement tolerance meets those parameters.

Labeled for success!

CI Vision's Pro Series offers a compact footprint and easy installation inside the labeler machine or on an adjacent conveyor. Though the Pro Series was built for a large company, its attractive price point gives advanced features to small packagers as well. The system is also compliant with the FDA's 21 CFR - Part 11 regulations on product tracking. Most of all, the Pro Series also gives CI Vision's customer the assurance that their brand's integrity will be maintained on a global scale.

For more information contact Media Relations.