Case Studies

Matrox Imaging Library Helps Delta Robot Sort Biscuits

The delta robot has been a fixture in assembly lines for over 20 years. And for good reasons. It's lightweight, nimble, and more flexible than an Olympic gymnast. Traditional robotic arms are modeled after human arms, where the motion of successive joints is dependent on bulky actuators and transmission mechanisms. The weight of these devices burdens the robot and slows the production speed.

In contrast, the delta robot, invented at the Ecole Polytechnique Fédéral de Lausanne (EPFL), has enjoyed many successes on the plant floor. Structured like an upside-down tripod, its three double legs form three closed loops, called "joint plan polygons". Each joint depends on the others, so if one segment moves, the others "follow" changing the whole polygon structure. Furthermore, the polygon structure means that actuators are not required on every joint, like they are in traditional robots. So on a delta robot, the actuators and transmission mechanisms can be placed away from the joint segments. Moving the clunky equipment away from the joints allows the delta robot to accelerate at a rate that's ten times faster than gravity.

The Swiss company Demaurex SA was one of the original license-holders of EPFL's delta robot technology. Today, Demaurex is known as Bosch Packaging Technology SA.

With 20 years of robotic vision and automation experience, it's no surprise that the technology still attracts a lot of attention. "Manufacturers are always trying to be more cost-effective. They want to reduce costs and be more competitive," explains Dragan Dragojlovic, Product Manager, about why customers approach Bosch. "The robots can run 24/7, and they don't get repetitive stress injuries like humans!"

Cookies galore!

A major European cookie and chocolate maker is one of several clients who work with Bosch to improve the efficiency of their factories. In one plant, this manufacturer outputs 30 million packages a year, and they contain over 80 different types of assorted cookies. This manufacturer needed a solution that could support the wide variety of products and a high throughput.

The Astor line of robots was the perfect candidate. The Astor features a vision-guided delta robot that can pick and place 140 units per minute. In this cookie packaging installation, there are eight robot cells on the plant floor that collectively sort 1 120 cookies per minute. Each cell sorts one or two cookie varieties for the package. As the blister tray passes each work cell, the robot stacks three or four cookies in the appropriate section of the blister tray.

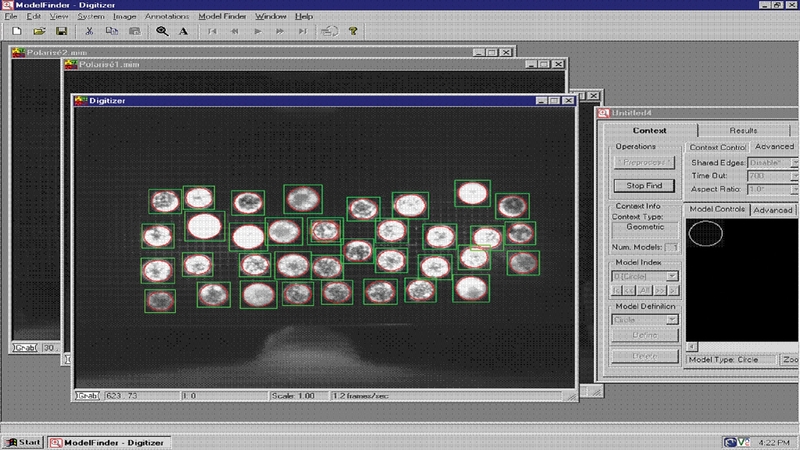

The robot cell is powered by a CELL in-house designed PC. Before a batch is packaged, an operator specifies the products and tray type that the robot will handle. A Sony XC-HR50 grayscale camera is installed inside an enclosure at the top of the machine, giving a bird's eye view of the conveyor. As the cookies travel, a Matrox 4Sight M embedded vision system signals the camera and a Matrox Meteor-II/Multi-Channel frame grabber acquires the images. The image acquisition and analysis software is based on the Matrox Imaging Library (MIL). Geometric pattern matching algorithms determine the shape and locate the specific cookies the robot must pick up. Grayscale analysis determines the quality of the cookie, and even the quality of the chocolate coating on the cookie. The analysis results also prevent the robot from placing broken or over-baked cookies into the package. Finally, the robot must place the top cookie right-side up in the tray; the image analysis ensures that the upside-down cookies don't make it to the top position in the stack.

Sprinkles, nuts, and other challenges

"The project demanded a lot of flexibility from a software standpoint," says Dragojlovic. "We needed the vision system to adapt to the variety of cookie shapes and sizes as well as color and shade to check for doneness." And with each circle, square, rectangle, triangle, heart and cigar located in an image, "we had to be sure that the acquired image is accurate," he adds. Good image results depend on proper illumination, and Dragojlovic says illuminating the work cell was a challenge. Chopped nuts and sugar sprinkles create shadows on cookies. Shiny chocolate coatings reflect light. Shadows and reflections are an image's worst enemy because they can interfere with the results. The software also had to account for parallax. In addition, the operator interface used during deployment required flexibility and simplicity, so the plant staff could easily set up the system for a different product on the feed line.

A taste of the future

Bosch Packaging Technology's Paloma, Delfi, and Astor lines are the three packaging systems that employ vision. They also conform to FDA and European regulations. Given the number of Bosch locations all over the world, Matrox Imaging tools are a good choice because "they are available globally." Dragojlovic is currently investigating the integration of Matrox Imaging smart cameras into some of the vision lines. But there's more than technical innovation that will keep Bosch at the top of its game. Dragojlovic says there's work to be done in promoting the use of vision in the food industry. "We don't use vision for some customers," he says, "because sometimes it's too complex for them. The food industry needs better information on the benefits of vision." This shouldn't be too difficult a task for a company whose competitors even say that they are the best. "We always do our best to find a solution," says Dragojlovic. "We have a fighting spirit!"

For more information contact Media Relations.