Case Studies

Machine Vision Helps Port Terminals Increase Productivity

Ship-to-shore container cranes rely upon Matrox Imaging smart cameras for safe and efficient shipping of cargo

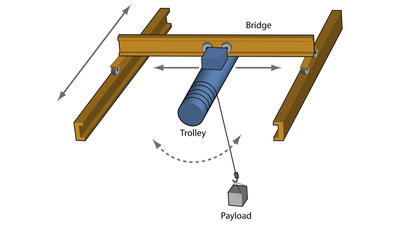

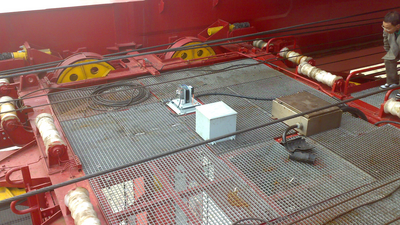

Ship-to-shore (STS) container crane

STS container crane anti-sway system

In an effort to transfer cargo containers faster and more safely, an increasing number of port operators now require that cranes be equipped with automated sensing and control systems to control load sway and to ensure that the spreader is optimally positioned. Source: MVLZ.

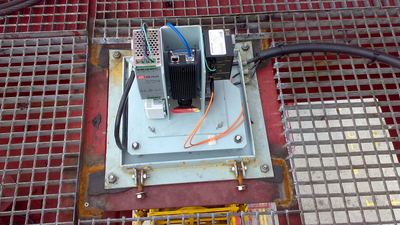

MicroView & LingZhi Image Tech Corporation (MVLZ) (Beijing, China) has developed an automated ship-to-shore anti-sway system that incorporates machine vision. The crane includes a machine vision system, a fiber optic communication link, PLC-based feedback control system, and an electronic control system. Source: MVLZ.

Machine vision’s role in anti-sway systems

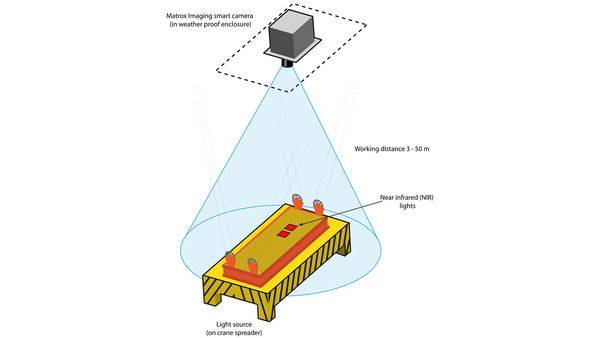

Smart camera-based vision system

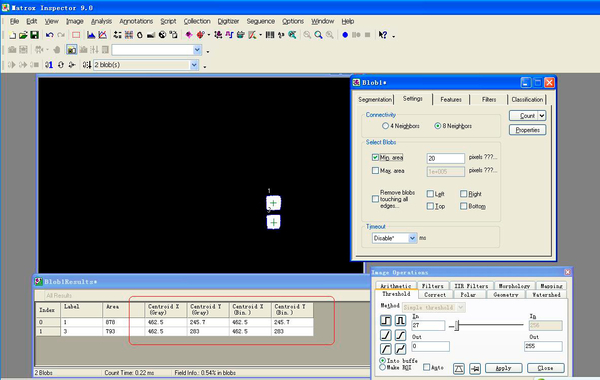

The sensor on the Matrox Iris smart camera can operate in the NIR range. Two custom NIR lamps are used as markers for imaging processing. “We chose NIR,” Ms. Xiao continues, “because it is immune to the effects of bad weather, like rain. A powerful light source is necessary to ensure that the markers are kept in the foreground, while everything else in the field of view is seen as background.”

The machine vision system is based upon a Matrox Iris smart camera. The light sources on the spreader are used as markers. The location of the markers' center point is continuously provided to the PLC. The PLC gives commands to the electronic control system, which regulates trolley movement so that container sway is reduced. Source: MVLZ.

The application was developed with Matrox Design Assistant, an integrated development environment (IDE) that is bundled with the smart camera. Design Assistant lets users create machine vision applications by constructing a flowchart instead of coding programs or scripts. “The smart camera software is very easy to use and does not require highly-skilled programmers. We simply initialize the serial port, grab the raw image, perform blob analysis, and write to the serial port,” explains Ms. Xiao.

Deployment

For more information contact Media Relations.