Case Studies

High-Speed Web Inspection Systems Use Machine Vision to Detect and Identify Defects

Matrox Imaging Library (MIL) and Matrox Camera Link frame grabbers enable 100% inspection of surfaces, printing and labels

Manufacturers of materials like plastics, papers, foils, films, metals and non-wovens produced in continuous rolls at very high-speeds rely upon machine vision-based web inspection to detect and identify defects. 100% surface inspection lets manufacturers remain competitive and meet regulatory requirements by identifying and resolving problems early in their production processes so defective goods do not reach the market.

Active Inspection, Inc. (AI) (Grand Rapids, MI) manufactures systems that perform 100% web inspection of surfaces, printing and labels. The AI Surface system inspects plastics, paper, foils, non-wovens and many other substrates, including coating and lamination processes used in converting applications. It includes adaptable filters to inspect glossy, matte and textured surfaces. The system also supports a multi-camera architecture to inspect a wide range of width and resolution combinations. AI Surface detects a variety of defects such as gels, skips, pinholes, roll-marks, holes and scratches.

How defects are detected depends upon whether the material being inspected has a uniform or textured surface. Identifying defects in uniform web materials like paper and metals rely upon finding areas that differ from that homogenous background. Identifying defects in textured surfaces presents more challenges as these defects are harder to define and characterize.

AI Surface includes up to eight Piranha2 or Piranha3 monochrome line-scan cameras from Teledyne Dalsa (P2-2x-04K40 or P3-8x-08k40), a high performance multi-CPU Windows-based workstation, digital I/Os and analog outputs from National Instruments (9421, 9472 and 9263 modules in a cDAQ-9174 USB chassis), Prophotonix Lotus LED line lights, a marker/tagger, an encoder and a Microsoft SQL database server. The cameras are interfaced to a Matrox Camera Link frame grabber, which offers FPGA-based processing offload capabilities.

Slower speed and lower resolution systems use two Piranha2 cameras connected to a Matrox Camera Link frame grabber while high-speed and high-resolution applications use four Piranha3 cameras connected to a Matrox Camera Link frame grabber. The images are processed using Matrox Imaging Library (MIL) image processing, blob analysis and calibration modules. Processing operations used include convolution, binarization, morphology (dilate and erode), flat-field correction and projection. AI Surface inspects a web that is 130 inches wide at a rate of 670 feet/minute. The inspection system can detect defects as small as 0.008 inch by 0.008 inch.

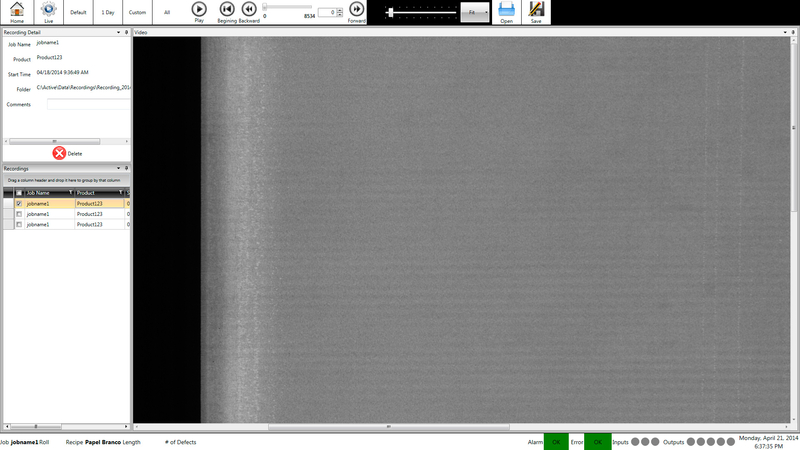

Designed to be used by touch screen, mouse or keyboard, the inspection system’s HMI focuses on ease-of-use and real time feedback so operators are experts after one work shift. At any time, an operator can record the complete web using a single touch. The data can be replayed back through the inspection system for tuning or for process analysis. Recordings can also be archived for later use, making this invaluable for process engineers. The user can display the complete web or sheet while using a second monitor for defect analysis and system operation. Different display options are offered such as last defect, selected region, or view the complete web or sheet.

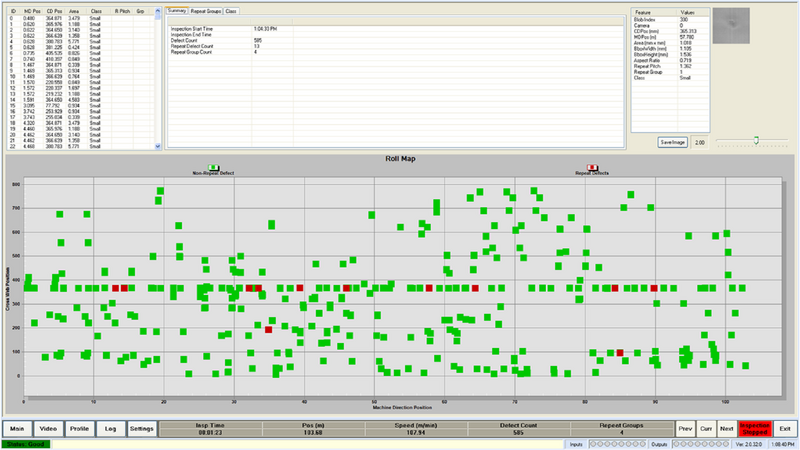

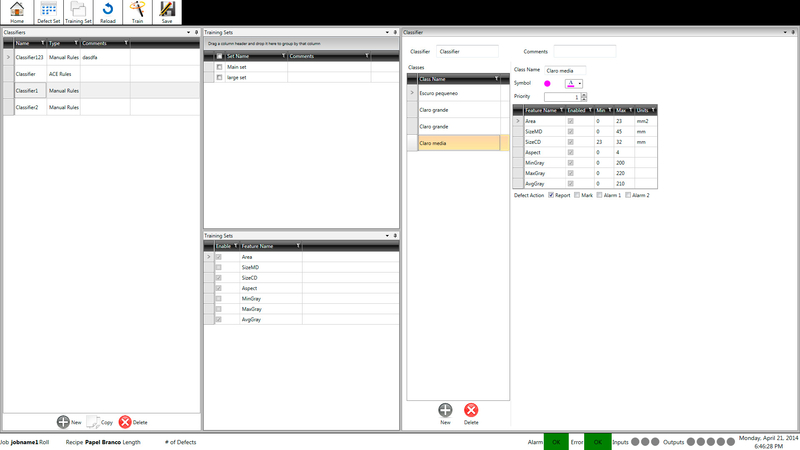

The HMI provides real time feedback and lets the operator tune the system to allow normal process variations while targeting real defects. The system includes access to a built-in classifier complete with a decision matrix. There is no limit to the number of recipes that can be stored, so specialized quality settings may be applied according to product, job, order or substrate. All relevant information including defect images are stored in easy-to-access XML file formats. These can then be used by Excel or any competent data mining software.

Alarms, flagging, machine control and waste removal are supported. When a serious class of defect occurs, the operator sees the defect on the screen and a designated action sequence is activated such as driving a downstream device to reject. A flag may be attached for roll to roll processes. AI also supports interfaces to enable smart coding for automated removal at slitting or doctor machines.

AI offers customers real-time inspection systems built with commercially available off-the-shelf hardware components and software. They are available in self-install kits that deliver a complete, 100% inspection solution that’s cost-effective, platform-independent and easy-to-use. Currently, 30 surface inspection systems are installed worldwide, in diverse industries that include aluminum manufacturing, plastics and engineered industrial product manufacturing, and paper mills.

The installation of an AI web inspection system has allowed customers like Knowlton Technologies, LLC (Watertown, NY) to improve product quality and significantly reduce labor costs. Beginning as a paper mill in 1808, Knowlton Technologies is now a world-leader in the design, accelerated prototyping and manufacture of wet-laid nonwovens in filtration, friction and custom designed composite webs.

Richard F. Barlow, Advanced Materials Engineer, explains the benefits that the mill realized from the install, “AI Surface let us remove three workers from a 100% manual inspection procedure and place them in higher value-added positions as soon as the system was installed, which allowed us to realize a quick return on our investment. Also, the user interface is set up so that is simple to create multiple custom classifiers for various customer needs and link to their specific grades. And our machine operators are very pleased with how easy it is to operate the inspection system.”

Looking to the future, Active Inspection plans to develop inspection systems using CMOS cameras that support higher line speeds. Also, AI will offer support for up to 16 cameras—currently a maximum of eight cameras are supported.

For more information contact Media Relations.